2.4.2: Fluid Milk Products

- Page ID

- 64458

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Milk Products

It is estimated that only about half of the milk that is consumed in the United States is in the form of fluid milk and cream. Milk is used as the base for many other food products such as: butter, cheese, yogurt, and ice cream.

Milk

There are 4 major forms of liquid milk sold in U.S. stores whole, reduced fat, low fat, and fat free/nonfat.

.jpg?revision=1)

Whole milk: to be whole milk, the milk must contain a minimum of 3.25% milk fat and at least 8.25% milk solids not fat (MSNF). Fortification of whole milk is an optional practice but many kinds of milk currently on the market are fortified with vitamins A and D.

Reduced fat and low-fat milk: this milk has had some of the fat removed. The percentage of fat found in these products can be on a range but are around 2% and 1% respectively. Similar to whole milk 8.25% MSNF must be present. These milk solids contribute to the consistency, taste, and nutrient profile of the product. Fortification with vit D is an optional practice while fortification with vitamin A is a mandated standard.

Fat-free or nonfat: Also referred to as skim milk, this milk has almost all of the milk fat removed (<.5%). Like other forms of milk 8.25% of MSNF is required to be present in the product. Fortification of vitamin A is a requirement for fat-free milk but fortification with vitamin D is optional.

Homogenized milk is fresh milk in which the fat particles are so finely divided and emulsified mechanically that the milk fat cannot separate on standing. The milk fat is forced into tiny droplets. More on this topic is discussed in the "Pasteurization and Homogenization" section of LibreText.

Pasteurization of milk was developed in 1859 by the French chemist Louis Pasteur. One method of pasteurization is to heat milk to above 71°C (160°F), maintain it at this temperature for a set time, then cool it immediately to 10°C (50°F) or lower. This kills all harmful bacteria that carry the potential threat of bovine tuberculosis and fever from cows to humans. More on pasteurization will be discussed in the "Pasteurization and Homogenization" section of LibreText.

Cream

The usual minimum standard for cream is 10% fat content, though it ranges between 10% and 18%. Cream in this range may be sold as light cream, half-n-half, heavy cream, or whipping cream. In order to produce these products, the cream is often removed and separated from the non-fat portion also known as skim milk and then various amounts of skim milk are added back to the cream to reach the desired fat percentage.

.png?revision=1)

Evaporated Milk

Produced by evaporating about 60% of the water found in whole milk. Because the milk is canned, often time stabilizers are added to prevent the separation of the fat in the liquid.

Also sold in a fat free version.

To reconstitute combine equal parts water.

Another canned milk product similar to evaporated milk is sweetened condensed milk. Often used in dessert preparation due to its high sugar content, condensed milk is produced by the evaporation of about 50% of the water and the addition of sugar. Due to the high sugar content this product does not have to be sterilized. Additionally, the high percentage of sugar, when heated in the canning process, produces a darker caramel-color.

.png?revision=1&size=bestfit&width=350&height=246)

https://www.thespruceeats.com/canned...g-tips-1808225

Milk Powder

Dried milk is often easier and more affordable to ship and has an extended shelf-life due to the removal of fat and water from the milk product. Powdered (dry milk) can be made from any of the forms of milk discussed previously (e.g. whole, reduced fat, skim). Vitamins A and D are required to be added in dry milk product that has been made using whole, or reduced fat liquid milk but remains optional in non-fat milk varieties.

Dried milk has a similar nutrient profile to liquid milk but vitamins may be reduced in the final product.

Instant milk is sometimes confused with powdered milk but they are not the same. Unlike powdered (dried) milk instant milk has the ability to agglomerate which means it can easily dissolve in water. It is made by taking non-fat dried milk and exposing it to steam which is then re-dried. Through this process it gains the ability to dissolve easily in water.

To use, mix approximately 1/3 cup instant milk to 1 cup of water.

Cultured Milk Products

Cultured milk products also known called fermented milk products have been a part of the human diet for just as long as milk has. It is often thought to have increased health benefits due to the addition of probiotics. Common products sold and consumed in North America include: buttermilk, yogurt, kefir, and sour cream. Bacterial cultures have been added in order to ferment the lactose (sugar found in milk) to lactic acid. The acid causes the casein (milk protein) to precipitate out of the product.

Cultures added diffe r and are not consistent in the production of all fermented foods. Food cultures include bacteria, mold, and yeast. These microorganisms can be present or added in the production process. There are no clear regulatory practices for the different microorganisms that are added to foods with the exception of yogurt which must have lactobacillus bulgaricus and streptococcus thermophilus added. When microorganisms are added they must appear on the nutrition label. If using naturally present bacteria or other organisms they are not required to be listed as an ingredient on the label.

r and are not consistent in the production of all fermented foods. Food cultures include bacteria, mold, and yeast. These microorganisms can be present or added in the production process. There are no clear regulatory practices for the different microorganisms that are added to foods with the exception of yogurt which must have lactobacillus bulgaricus and streptococcus thermophilus added. When microorganisms are added they must appear on the nutrition label. If using naturally present bacteria or other organisms they are not required to be listed as an ingredient on the label.

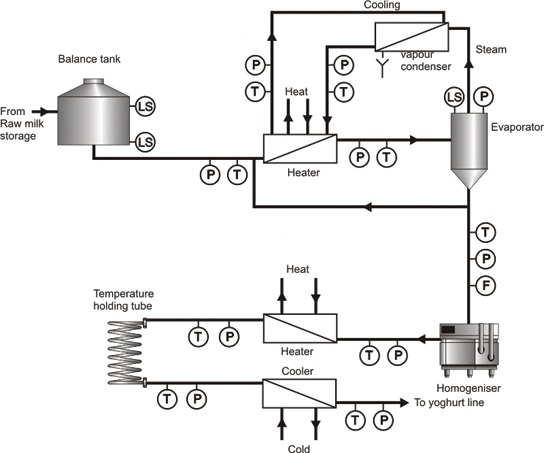

Yogurt Production:

Yogurt has been around for several millennia. The mythological story about the discovery of yogurt suggests that sheepherders stored their milk in bags made of the intestinal gut of the animals. The intestines contain natural enzymes that cause the milk to curdle and sour. This soured milk lasted longer so they continued making it. Today, the FDA defines yogurt as a milk product fermented by two bacterial strains: a lactic acid-producing bacteria: Lactobacillus bulgaricus and Streptococcus thermophiles.

Probiotics

Yogurt cultures in the intestinal tract have been shown to release the enzyme lactase which continues to break down lactose in the dairy product. This makes yogurt edible for people who are lactose-intolerant.

Kefir

Kefir is a carbonated fermented milk drink. The microbes involved in the production of kefir are a symbiotic culture of lactic acid bacteria and yeasts embedded in a matrix of proteins, lipids, and polysaccharides, ‘kefir grains’.

Sour Cream

Sour cream is made from cream soured by adding lactic acids and thickened naturally or by processing. The lactic acid causes the proteins in sour cream to coagulate to a gelled consistency.

Buttermilk

There are two methods to produce buttermilk:

- Inoculating milk with a specific culture to sour it

- Churning milk and separating the liquid left over from the butter

The second method is where buttermilk gets its name, but today, most of what is commonly called buttermilk is the first type. Buttermilk has a higher acid content than regular milk (pH of 4.6 compared with milk’s pH of 6.6).

The fermented dairy product known as cultured buttermilk is produced from cow’s milk and has a characteristically sour taste caused by lactic acid bacteria. This variant is made using one of two species of bacteria — either Lactococcus lactis or Lactobacillus bulgaricus, which creates more tartness in certain recipes.

The acid in buttermilk reacts with the sodium bicarbonate (baking soda) to produce carbon dioxide, which acts as the leavening agent.

Source: Understanding Food Principles and Preparations Amy Brown 4th edition