6.1.1: Sugar (sucrose)

- Page ID

- 64566

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Sugar (Sucrose)

For the remainder of this section, we will be referring to sugar generally to mean sucrose and its derivatives.

Sugar is a natural food. Chlorophyll, the green coloring matter in plants, is the key to the natural production of sugar. The process used by green plants is called photosynthesis. Plants build all other food substances, such as protein and oil, directly or indirectly from this sugar.

The two plants that yield the most sugar and are commercially grown are sugar cane and sugar beet. Raw sugar is made in large refineries by crushing cane sugar (Sacchrum officinarum) or beet root (Beta vulgaris) to obtain juice. Boiling the juice removes water, and with further processing, unrefined raw sugar is obtained (sometimes also known as panela). Generally, cane sugar is produced by tropical countries and the beet sugar by cooler, temperate areas.

Sugar cane is actually a giant grass that stores sugar in its stalk and is a renewable resource. In other words once it is planted it can be harvested again and again without replanting. It is grown in warm, moist countries, and cane accounts for approximately 80% of the world’s sugar; the remaining 20% is produced from sugar beet. Brazil and India are the largest cane producers, with Brazil alone accounting for over 25% of the world’s sugar. Other producing regions significant to North America’s sugar supply are Thailand, China, Hawaii, the Caribbean, Philippines, and Australia.

Sugar beet was developed in the early 1800s. Since that time, sugar beet farming has spread to all parts of the temperate climatic zone. A root crop, it is more tolerant of northern climates and is grown as far north as Minnesota and Michigan in the United States.

- The link bellow provides more details on where sugar comes from:

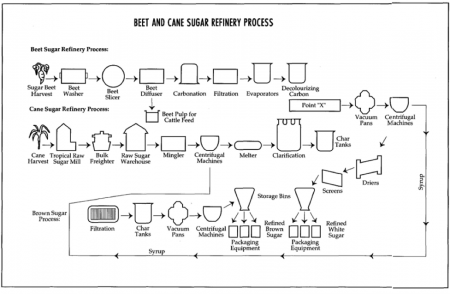

Figure 1. Sugar refining process.

Figure 1. Sugar refining process.Sugar Chemistry

Chemically, sugar consists of carbon (C), oxygen (O), and hydrogen (H) atoms, and is classified as a carbohydrate. There are three main groups of sugars, classified according to the way the atoms are arranged together in the molecular structure. These groups are the following:

- Monosaccharides or simple sugars. Dextrose (glucose) is the major monosaccharide. Others are levulose or fructose (found in honey and many fruits), and galactose, which is a milk sugar. Such sugars do not readily crystallize. (Mono means one, indicating that the sugar consists of only one molecule.)

- Disaccharides or complex sugars. Sucrose (common sugar) is the primary example of a disaccharide. Maltose, found in cereals, and lactose, found in milk, are others.

- Polysaccharides. Examples are starches, dextrins, and cellulose.

Sugar Refining

While some refining usually occurs at source, most occurs in the recipient country. The raw sugar that arrives at the ports is not legally edible, being full of impurities.

At the refinery, the raw brown sugar goes through many stages:

- Washing and boiling

- Filtering to remove impurities

- Evaporation to the desired crystal size under vacuum to avoid caramelization

- Centrifuging, in which the fluid is spun off leaving the crystals

- Drying in a rotating drum with hot air

- Packaging in various sizes, depending on the intended market

Sugar beet undergoes identical steps after the initial processing, which involve:

- Slicing the beets and extracting the sugar using hot water

- Removing impurities

- Filtration

- Concentration in evaporators

From here, the process is identical to the final steps in cane processing. See Figure 2 which illustrates the process.

Some of the sugar passes through a machine that presses the moist sugar into cubes and wraps and packages them; other sugar is made into icing sugar. The sugar refining process is completely mechanical, and machine operators’ hands never touch the sugar.

Brown and yellow sugars are produced only in cane sugar refineries. When sugar syrup flows from the centrifuge machine, it passes through further filtration and purification stages and is re-boiled in vacuum pans such as the two illustrated in Figure 2. The sugar crystals are then centrifuged but not washed, so the sugar crystals still retain some of the syrup that gives the product its special flavor and color.

During the whole refining process almost 100 scientific checks for quality control are made, while workers in research laboratories at the refineries constantly carry out experiments to improve the refining process and the final product. Sugar is carefully checked at the mills and is guaranteed to have high purity.

Are animal ingredients included in white sugar?

Bone char — often referred to as natural carbon — is widely used by the sugar industry as a decolorizing filter, which allows the sugar cane to achieve its desirable white color. Other types of filters involve granular carbon or an ion exchange system rather than bone char.

Bone char is made from the bones of cattle, and it is heavily regulated by the USDA. Only countries that are deemed BSE-free (bovine spongiform encephalopathy) can sell the bones of their cattle for this process.

Bone char is also used in other types of sugar. Brown sugar is created by adding molasses to refined sugar, so companies that use bone char in the production of their regular sugar also use it in the production of their brown sugar. Confectioner’s sugar — refined sugar mixed with cornstarch — made by these companies also involves the use of bone char. Fructose may, but does not typically, involve a bone-char filter.

If you want to avoid all refined sugars, there are alternatives such as sucanat and turbinado sugar, which are not filtered with bone char. Additionally, beet sugar — though normally refined — never involves the use of bone char.

Types of Sucrose:

Sugar in its various forms is the third most used ingredient in the bakery, exceeded only by flour and water. The following sections describe the forms of sugar available to bakers, and Table 2 shows the differences in composition of the leading types.

Cube Sugar

Cube sugar, or lump sugar, is made from the first refined syrup, which is the highest grade. It is formed in molds while the sugar is still moist, then dried in ovens and packed. Cube sugar is excellent for sugar boiling in caramel work.

Granulated Sugar

Refined granulated sugar is the most common form of sugar used. It is produced in various crystal sizes (fine, super fine, and berry are a few). Custom sizes are also available from some manufacturer, since any size crystal is possible at the factory depending on when the process is halted.

Liquid Sugar

Some food manufacturers prefer this mixture of water and sugar. Liquid sugar is metered into the manufacturing process. There are many grades and blends of liquid sugar tailored to suit food manufacturers’ requirements.

Invert Sugar

When water and sugar are heated in the presence of a weak acid solution and/or enzymes, the sucrose breaks up into sweeteners of simpler chemical structure, creating invert sugar. A similar process occurs in the stomach. Like commercial glucose, invert sugar is a thick, colorless syrup and consists of 38% dextrose, 38% levulose, and 24% water. It is slightly sweeter than sucrose and is popular with some industrial users like soft drink bottlers and confectioners. Invert sugar is a good example of a monosaccharide — that is, despite the presence of a high concentration of sugar, it stays as a thick syrup.

Castor Sugar

Use the link below to learn more about castor sugar:

https://www.webstaurantstore.com/blog/2584/what-is-caster-sugar.html

Icing Sugar

Also known as confectionary or powdered sugar, icing sugar is produced by grinding high-grade crystals. This sugar passes through a series of sieves, yielding a selection of icing sugars. Icing sugar contains from 3% to a maximum of 5% starch (either cornstarch or wheat starch) to retard lumping or crystallization. Tricalcium phosphate may be added in the United States at a level of 1% for the same purpose.

Note: Icing sugar that contains wheat starch is not a gluten-free ingredient!

Sanding Sugar

Use the link bellow to learn more about sanding sugar:

https://www.bobsredmill.com/blog/baking-101/what-is-sanding-sugar/

Brown Sugar and Golden (Yellow) Sugar

Brown sugar, light brown sugar, and yellow sugar are refined products containing molasses flavored syrup giving the products a distinctive taste and color. They are available in a variety of grades and colors and are soft sugars.

Keep this sugar moist. If stored in dry conditions, the sugar becomes lumpy and hard. If the ambient humidity is high, the sugar can be left exposed. If the air is dry, it must be kept well covered.

Molasses

Molasses is a by-product of the cane and beet refining processes. Cane sugar molasses is edible and comes in many grades from fancy to black strap molasses. Sugar beet molasses is non-edible but has other industrial uses. Molasses is also available in dry form.

Turbinado Sugar

Use the link bellow to learn more about turbinado sugar.

Raw Cane Sugar

Visit the link below to learn more about raw cane sugar:

Sweetness in Sugar

Sweetness is influenced by many factors including temperature, pH, and the presence of other substances that need not themselves be sweeteners. The relative sweetness of sugar and other carbohydrate sweeteners is shown in Table 3. Note that sucrose is the reference standard to which all the other types of sugar are compared. This reference is called the sweetness equivalent.

| Type of Sugar | Sweetness Equivalent |

|---|---|

| Fructose/levulose | 1.73 |

| Invert sugar | 1.30 |

| Sucrose | 1.00 (reference) |

| Glucose/dextrose | 0.74 – 0.80 |

| Sorbitol | 0.60 |

| Mannitol | 0.50 |

| Maltose | 0.33-0.45 |

| Galactose | 0.32 |

| Lactose | 0.16 |

What this table tells us is that mannitol, for example, is only half as sweet as sucrose. Therefore, two level teaspoons of mannitol would be needed in a cup of coffee to obtain the same sweetness level as one teaspoon of sucrose.

Media Attributions

- Sugar refining process © Baking Association of Canada